Services and fields of intervention

The areas of application of our products are multiple and vary based on the radio frequencies used.

The areas of application of our products are multiple and vary based on the radio frequencies used.

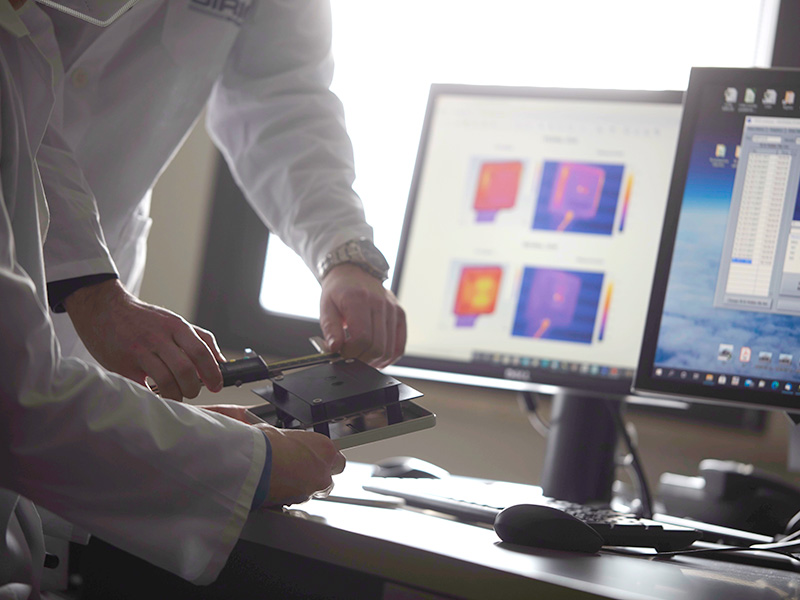

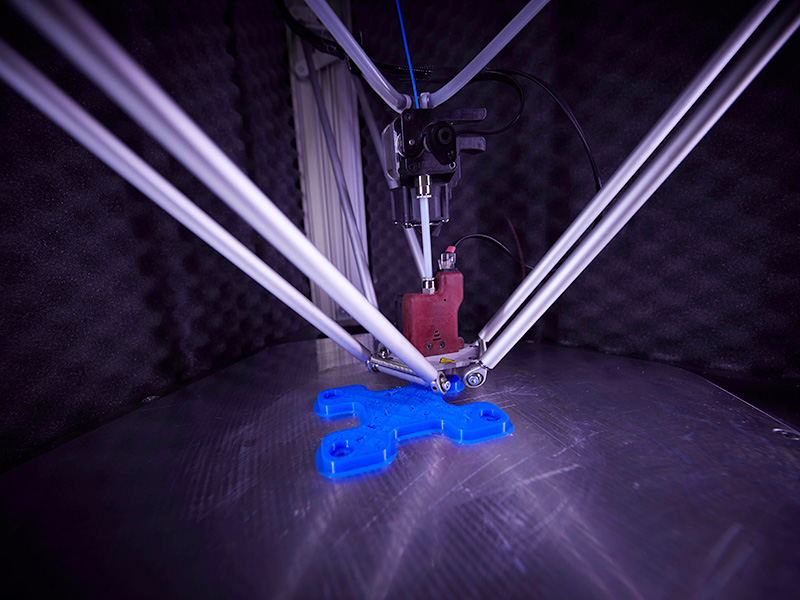

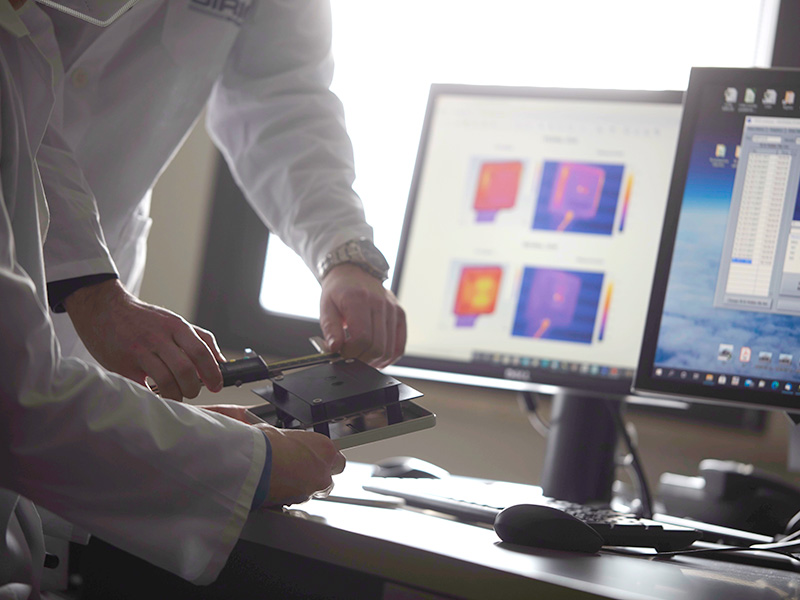

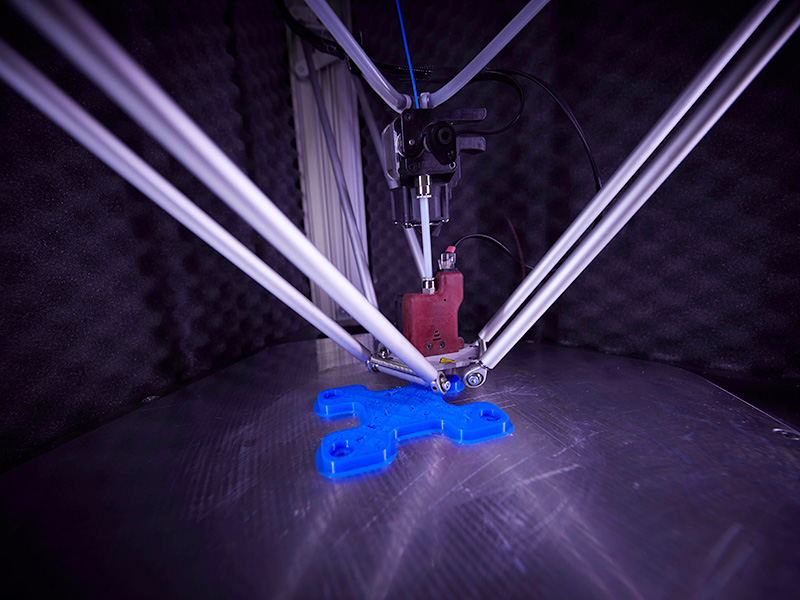

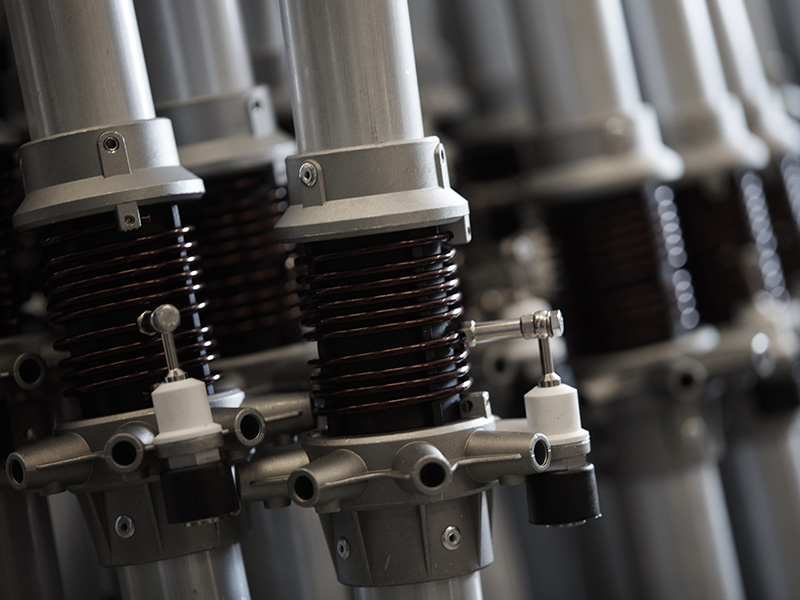

Our R&D is dedicated to the research, development and optimization of new products and production processes and is structured with cutting-edge instrumentation, electromagnetic simulation software, an anechoic chamber to test the electrical characteristics of the antenna in an environment free of interference, climatic chamber to verify product performance at extreme temperatures and humidity.

Our equipment is state of the art to ensure the highest quality possible.

Our R&D is dedicated to the research, development and optimization of new products and production processes and is structured with cutting-edge instrumentation, electromagnetic simulation software, an anechoic chamber to test the electrical characteristics of the antenna in an environment free of interference, climatic chamber to verify product performance at extreme temperatures and humidity.

Our equipment is state of the art to ensure the highest quality possible.

We take care of business administration, Foreign and Italian sales, Purchasing, Logistics IN/ OUT, Human Resources.

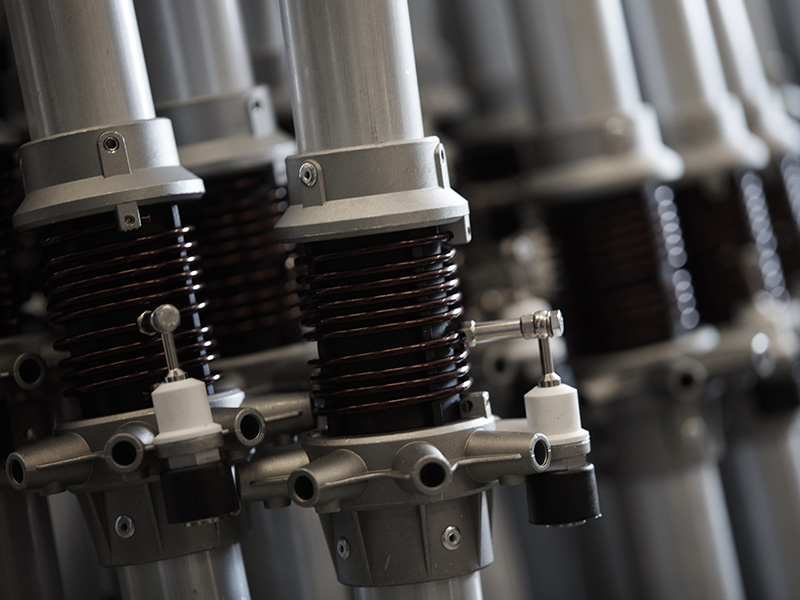

All production, assembly, product testing, packaging and shipping processes are 100% made in Italy at our plants in Volta Mantovana. Subcontractors of spare parts are directly managed by our purchasing department and controlled by our Quality Control.

We take care of business administration, Foreign and Italian sales, Purchasing, Logistics IN/ OUT, Human Resources.

All production, assembly, product testing, packaging and shipping processes are 100% made in Italy at our plants in Volta Mantovana. Subcontractors of spare parts are directly managed by our purchasing department and controlled by our Quality Control.

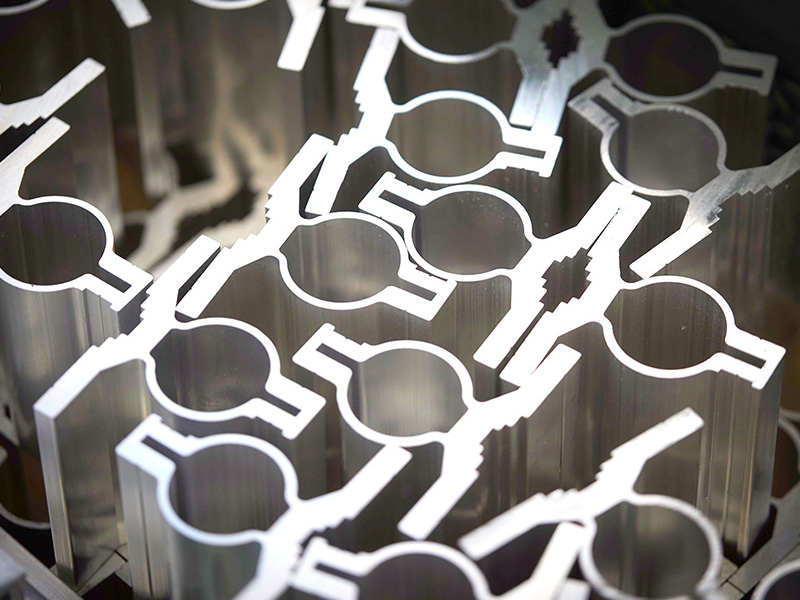

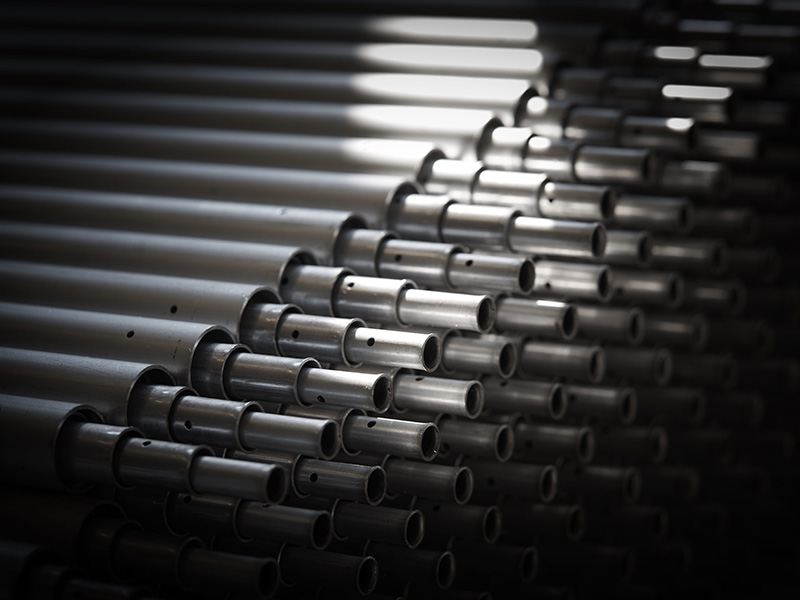

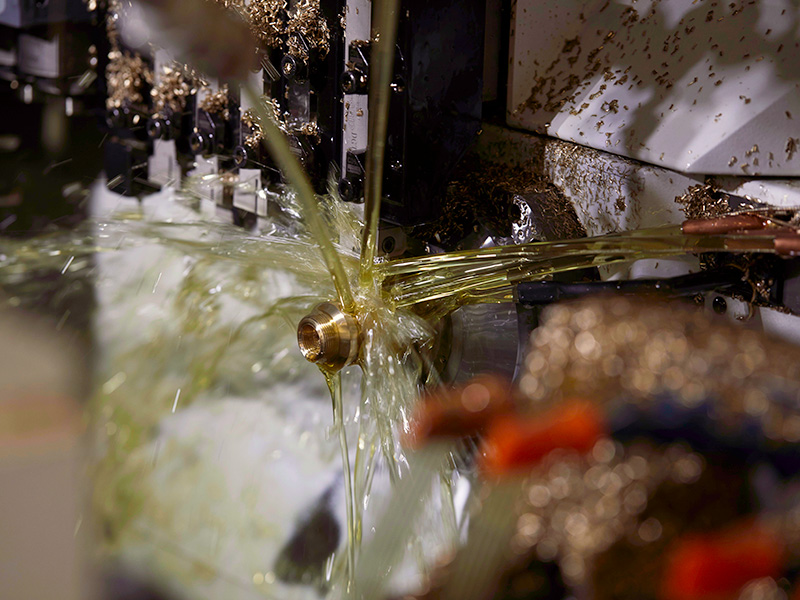

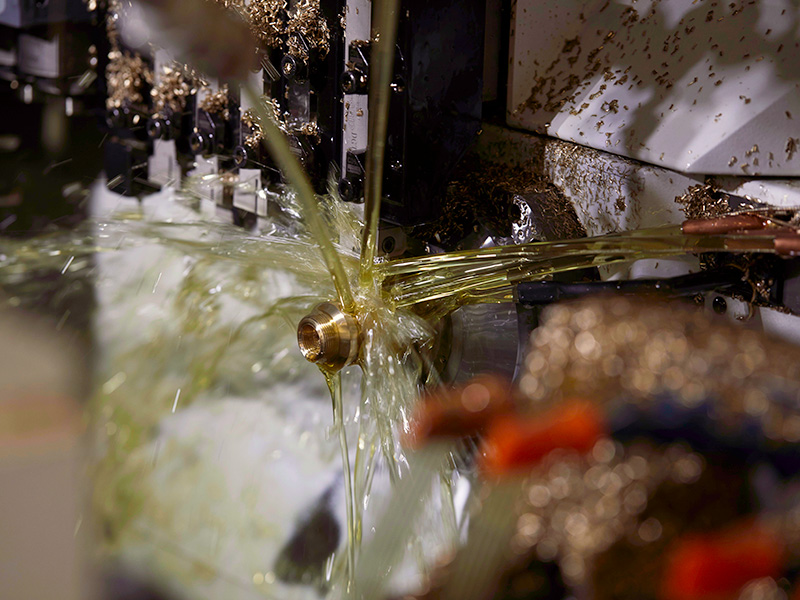

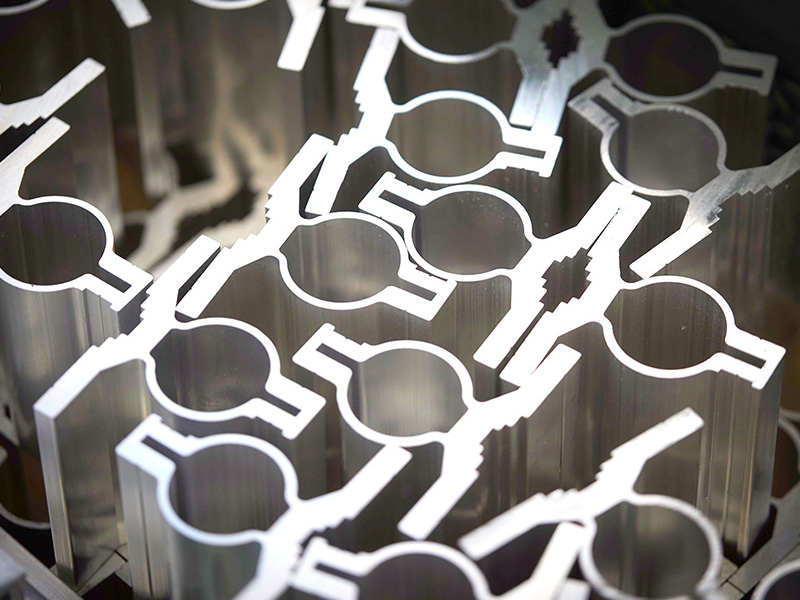

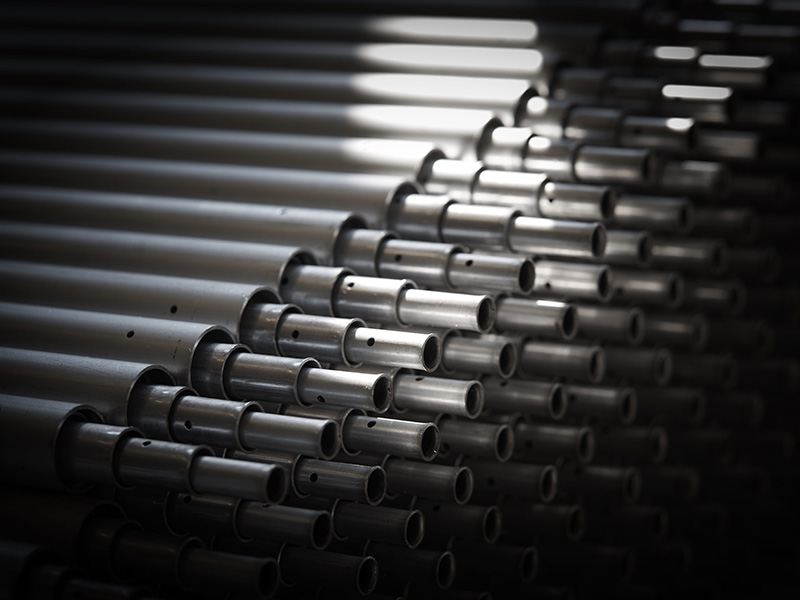

Our workshop covers 800sqm and is equipped with CNC lathes, machining center, automatic parts washing. Equipment that allows the company maximum flexibility and speed in the realization of our standard production, prototypes and/or 'Custom' projects.

Our workshop covers 800sqm and is equipped with CNC lathes, machining center, automatic parts washing. Equipment that allows the company maximum flexibility and speed in the realization of our standard production, prototypes and/or 'Custom' projects.

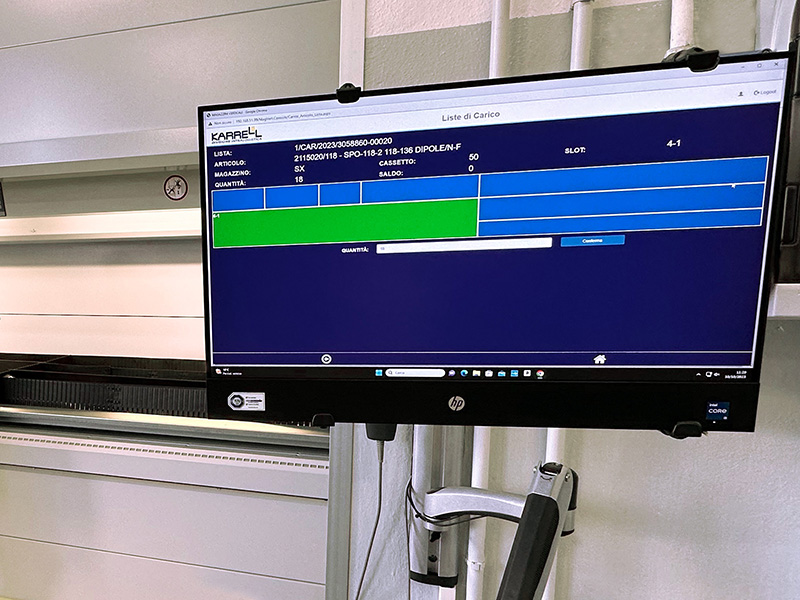

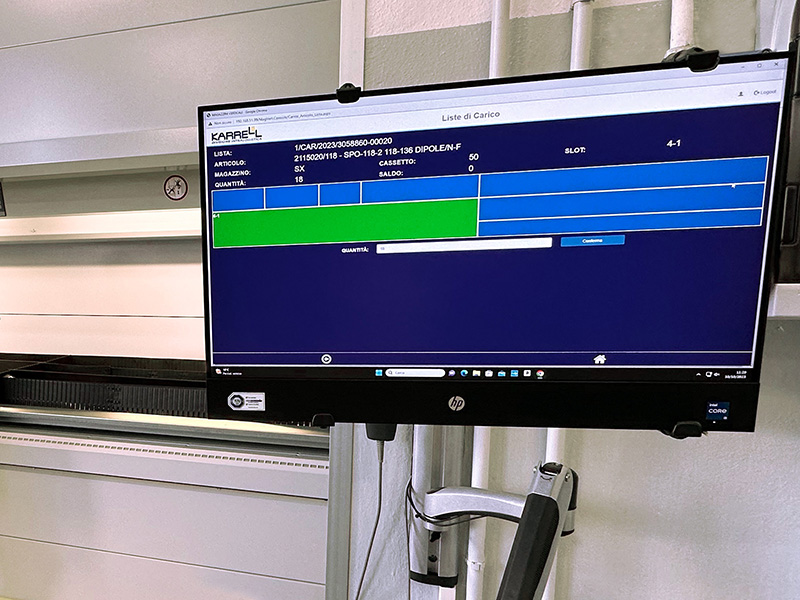

In 2022, 2 new automatic VERTICAL warehouses have been installed to stock more than 700 ready-made products to allow quick deliveries across the National territory, guaranteeing delivery within 12-24 hours from the order.

SIRIO warehouse, with over 2000 components, guarantees a fast and rapid service, allowing delivery within 3-4 weeks.

In 2022, 2 new automatic VERTICAL warehouses have been installed to stock more than 700 ready-made products to allow quick deliveries across the National territory, guaranteeing delivery within 12-24 hours from the order.

SIRIO warehouse, with over 2000 components, guarantees a fast and rapid service, allowing delivery within 3-4 weeks.